Ultralight superconducting MgB2 wires

In the Department of Superconductors we have developed an ultralight superconducting wire suitable for windings generating strong magnetic fields at temperatures close to 20 K (-253 °C), accessible via the cryo-coolers (without liquid Helium). The basic idea was to combine the lightest existing superconducting compound MgB2, having the density of 2.55 gcm-3, and very light metals: diffusion barrier from Titanium (4.5 gcm-3) and Aluminum outer sheath (2.7 gcm-3). Such superconducting wire is attractive for future use in wind power generators, aircraft motors and also as active magnetic shielding during long-term space missions.

The goal was to develop an ultralight MgB2 wire with a cross-section of about 1 mm2 and decent superconducting properties, especially high critical current densities in the 0 – 5 T magnetic field range, robust mechanical properties and low AC losses in the 1 – 100 Hz frequency range. Therefore, the preparation method of Mg diffusion and infiltration into the densified Boron powder was chosen, with a subsequent fast intermetallic MgB2 phase formation at temperatures around 650 °C.

The research was fostered by our long-time experience with preparation of filamentary superconducting wires. We have experimentally verified that the most used diffusion barrier material Nb (8.5 gcm-3) can be replaced with a lighter and easily cold-formable material Vanadium (6.0 gcm-3) and especially with Titanium (4.5 gcm-3). Both these metals do not react with Mg and B during the final heat treatment. However, the properties of the pure Aluminum (its softness) do not allow the preparation of composite wire using rolling or drawing. We have therefore tested the originally construction material Al+Al2O3 called HITEMAL®, developed at the Institute of Materials and Machine Mechanics SAS employing the powder technology. Molded parts from Al+Al2O3 were formed into thin wires and were thoroughly tested mechanically and electrically at room and low temperatures. This material showed good mechanical and electric properties and was used for manufacturing the lightest superconducting wire based on MgB2.

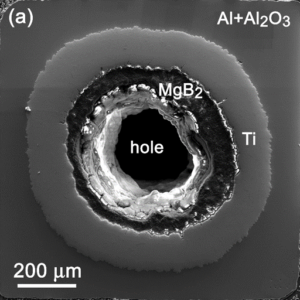

Technological process was based on forming of the central Mg wire surrounded with the Boron powder in Ti tube placed in an outer tube from Al+Al2O3 (HITEMAL®). This composite was rolled at cold until the final dimension of approximately 1 mm and underwent the final heat treatment, Fig. 1.

Fig. 1: Cross-section of the superconducting wire with the MgB2 phase, Ti barrier and the Al+Al2O3 sheath.

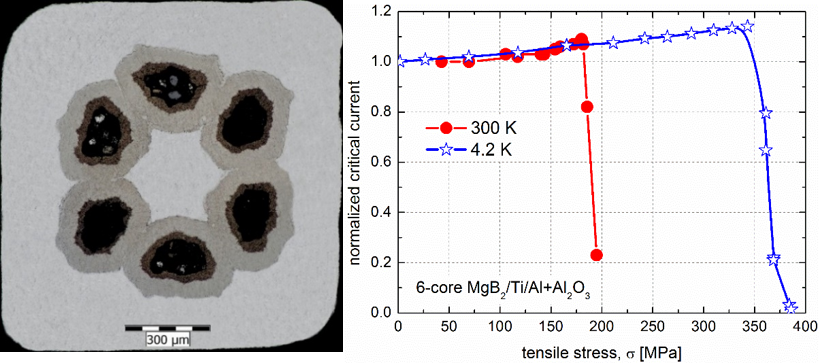

Very encouraging results paved the way to testing of sheaths with different Al2O3 content and further to preparation of a 6-filament wire with a remarkable robustness at tensile loading – Fig. 2.

Fig. 2: Cross-section of the 6-filament wire 1.16 x 1.16 mm2 and its behavior in tensile loading at the room temperature (300 K) and at the liquid helium temperature (4.2 K).

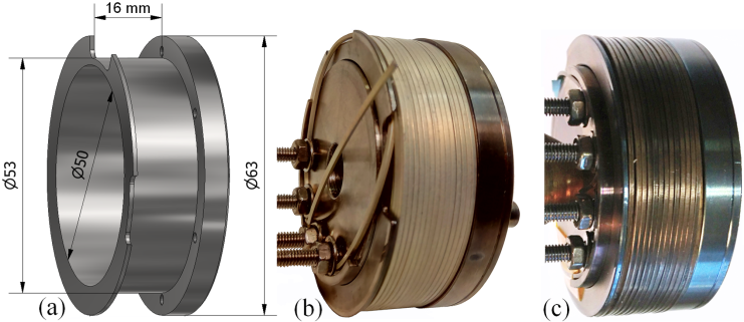

Significant advantage of an Aluminum based outer sheath is the possibility of insulating the wire by simple oxidation of its surface, producing a thin Al2O3 layer with a very good thermal conductivity, resistance against high temperature and good insulation properties in a winding. Application of this unique insulation was successfully tested on a superconducting coil wound from an MgB2/Ti/Al+Al2O3 wire, Fig. 3, on a support from stainless steel. This lightweight winding shows a very good insulation efficiency and particularly high filling factor (above 90%), which enables to further minimize the volume and weight of windings for the real-world applications.

Fig. 3: Stainless steel support (a), coil wound from the Mg/B/Ti/Al+Al2O3 wire insulated by a thin Al2O3 layer (b) and the heat-treated winding with the MgB2 phase (c).

Santra, S., Grovenor, C.R.M., Speller, S.C., Kováč, P., Kopera, L., and Hušek, I.: Comparison of interfacial and critical current behaviour of Al+Al2O3 sheathed MgB2 wires with Ta and Ti diffusion barriers, J. Alloys Comp. 807 (2019) 151665

Kováč, P., Kopera, L., Kováč, J., Melišek, T., Haessler, W., Wang, D., and Ma, Y.: Current densities and strain tolerances of filamentary MgB2 wires made by an internal Mg diffusion process, Supercond. Sci Technol. 32 (2019) 095006

Kováč, P., Bonura, M., Santra, S., Kopera, L., Rosová, A., Senatore, C., and Hušek, I.: Thermal conductivities and thermal runaways of superconducting MgB2 wires stabilized by an Al+Al2O3 sheath, Supercond. Sci Technol. 32 (2019) 115007

Kopera, L., Kováč, P., Kováč, J., Melišek, T., Hušek, I., and Berek, D.: Small diameter wind and react coil made of anodised Al-sheathed MgB2 wire, Supercond. Sci Technol. 32 (2019) 105003

Kováč, P., Hušek, I., Rosová, A., Melišek, T., Kováč, J., Kopera, L., Scheiter, J., and Haessler, W.: Strong no-barrier SS sheathed MgB2 composite wire, Physica C 560 (2019) 40-44

Contact

Contact Intranet

Intranet SK

SK