Rutherford MgB2 cable

Figure shows the cross-section and longitudinal view of the first Rutherford MgB2 cable with visible components of individual wires. Lossless transport of direct electric current is carried by MgB2 core in the middle of each wire, which is protected by titanium diffusion barrier against the layer of stabilizing high purity copper. Improved mechanical tolerance is enabled by the outer sheath made of Cu-Ni alloy (Monel). Individual wires are transposed into the cable by planetary braiding system and by forming rolls. Increased fill factor in flat cable allows to improve the engineering current density Je by more than 20% and offers also possibility of winding to small diameters (»40 mm) without any degradation of transport currents, which is especially important for wind turbines with large number of poles.

Kopera, Ľ., Kováč, P., Hušek, I., and Melišek, T.: Rutherford cable made of single-core MgB2 wires, Supercond. Sci Technol. 26 (2013) 125007.

Hušek, I., Kováč, P., Melišek, T., and Kopera, Ľ.: Transport current densities of MgB2 wire, cable and continually transposed conductor, Cryogenics 49 (2009) 366-370.

Kováč, P., Hušek, I., and Melišek, T.: MgB2 cable made from two-axially rolled wires, Supercond. Sci Technol. 21 (2008) 125003.

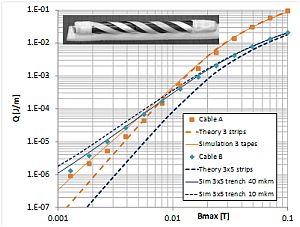

Low AC loss cable produced from transposed striated CC tapes

In this work we demonstrate that the use of striated tapes from coated conductors (CCs) significantly reduces the dissipation of a cable made of tapes wound helically on a round core when it is exposed to AC magnetic field. We compare the magnetization loss in two cable models of identical geometry: The reference one from as-received tapes and the other one from the tapes striated to 5 filaments. The cable length was designed to reach two complete tape pitches. The AC loss was measured for cables without terminations as well as with low resistance terminations; this latter configuration simulates the conditions in a magnet winding. Our experiments have clearly shown the loss behavior expected in the regime of uncoupled filaments. At AC fields of 0.1 T amplitude the loss in the cable from striated tapes is five times lower than in the reference cable. Numerical models have explained the experimentally observed cable behavior in the whole range of AC fields.

Fig.: AC loss measured on two small cable models at 72 Hz, 77 K: Cable A from standard tapes, Cable B from striated tapes. Long-dashed lines show simple analytical predictions. Short-dashed lines in reasonable agreement with experimental data have been obtained by numerical finite element modeling.

Šouc, J., Gömöry, F., Kováč, J., Nast, R., Jung, A., Vojenčiak, M., Grilli, F., and Goldacker, W.: Low AC loss cable produced from transported striated CC tapes, Supercond. Sci Technol. 26 (2013) 075020.

Contact

Contact Intranet

Intranet SK

SK